The June, 2017 issue of Foundry Magazine features an article by Trent Blake which addresses the silica rule currently in effect.

The new standard, to be enforced starting on July 23, 2018, is half of the previous standard and “requires metal casters to prove that they have implemented all feasible engineering and work practice controls to reduce silica exposure to employees”.

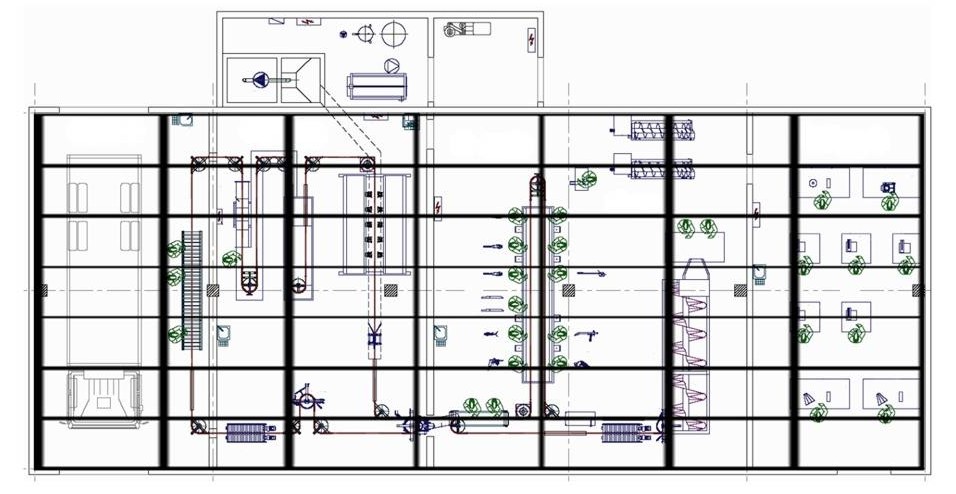

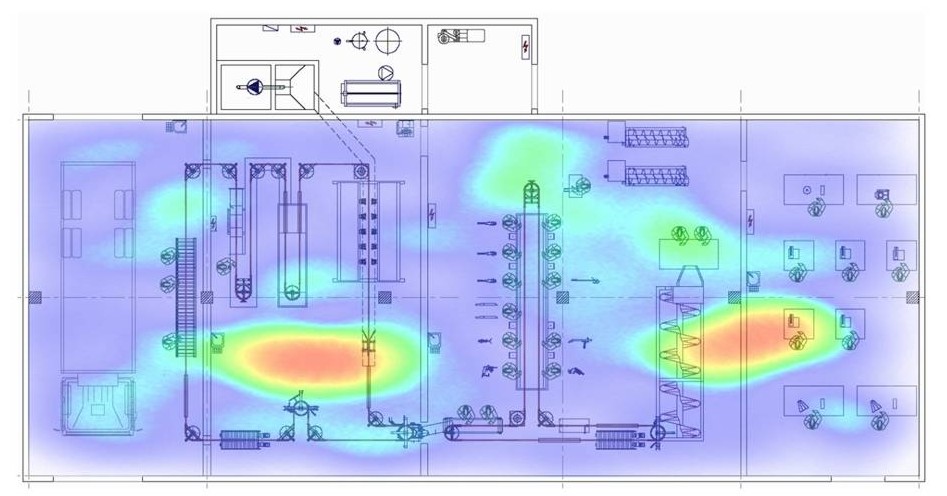

KERAMIDA and Foundry Solutions & Design have formed a partnership to offer the industry a comprehensive resource to develop sampling methods resulting in a silica concentration map of the facility.

This “mapping” strategy allows for an engineering solution to be implemented for reducing the silica at the source.

For additional information please click on the link below