To maintain the molding production rate in a foundry it is crucial to have cores available when needed. Molding lines typically run at a higher rate than core production and, as it is normally not cost effective to size the core production to match the molding line speeds, most of the time core shops run longer hours than mold lines. In addition to this, sometimes foundries purchase cores to meet the demand. Either way, there needs to be a means to store cores.

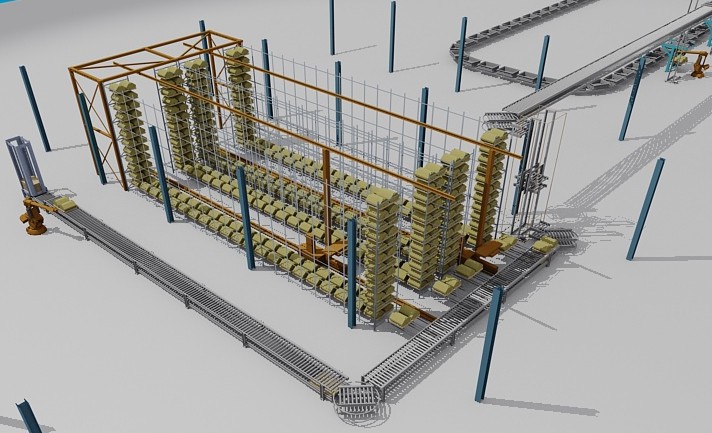

Solutions include: a Core Buffer/Storage System, Core Delivery System, and optionally an Automated Core Setting device. FS&D can design different approaches, depending on customer needs, production rates, and delivery methods. It can be as simple as multi-level rolling carts for storage, gravity roller conveyor systems, or a fully automated gantry storage system with individual pallets that hold a complete set of cores for each mold.

Robotic Core Pallets unload and Core setting in the mold

Robotic Core Pallets unload and Core setting in the mold