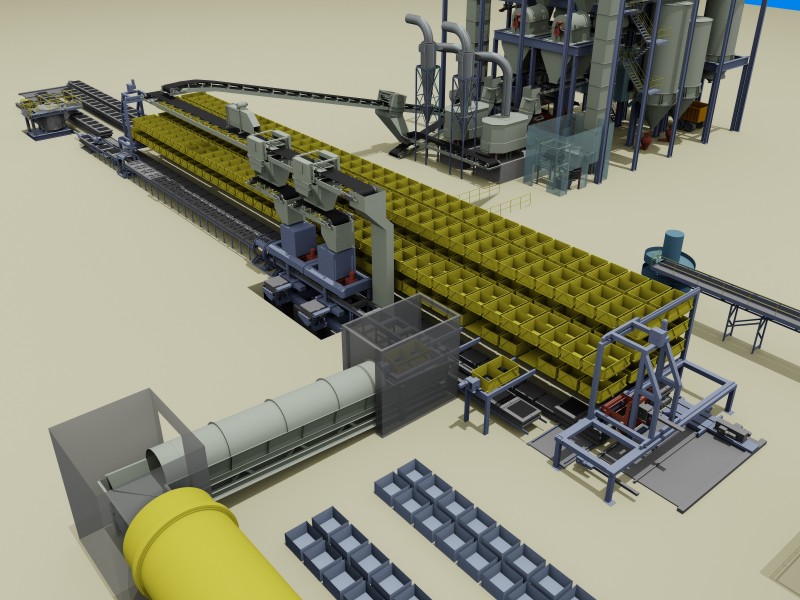

In-mold and post-shakeout casting cooling are processes which have traditionally required substantial investment and manufacturing floor space. FS&D optimizes this process by integrating this equipment in a self-contained environmental enclosure and isolating the dust, heat, and noise from operating personnel. By utilizing vertically arranged conveyors, inexpensive casting jackets, selective cooling time, and forced air flow these processes can be accomplished in less time, with far less floor space, in an environmentally safe manner, and at a lower investment cost.

Cooling house details

Horizontal molding line with the flask and jackets

Magaldi sorting conveyor with the patented air flow cooling